Living Wall Irrigation Mistakes: The Hidden Dangers of Copper Pipes

When designing living walls—also known as vertical gardens or green wall systems—specifying the right irrigation materials is critical to long-term plant health and performance. While it’s common to call for “non-corrosive piping” such as Schedule-40 PVC, CPVC, or PEX tubing, there’s still pushback on many projects, especially in cities like New York City, where commercial buildings often insist on using copper plumbing for everything.

However, when fertilizer is introduced, the copper pipes will gradually corrode—and the resulting toxicity can harm or even kill the plants.

Why the (Unnecessary) Push for Copper Pipes in Living Walls when there are Safer Non-Corrosive Alternatives?

Copper piping is widely accepted in commercial buildings due to its proven safety for potable water, compatibility with both hot and cold temperatures, compliance with building codes, and resistance to UV degradation. Because of this, most plumbers keep a steady inventory of copper on hand.

However, it's important to note that in living wall systems, the irrigation piping is used exclusively for non-potable operations. These lines typically run short, direct paths from the irrigation unit to the wall and would never be connected to drinking fountains, kitchen sinks, or any potable water sources.

Materials like Schedule 40 PVC, CPVC, and PEX are not only suitable for non-potable operations, but they are often significantly cheaper per linear foot compared to copper. This makes them an economical and effective choice—particularly for the short, targeted piping runs typical in living wall installations.

While many plumbers default to copper out of convenience or code familiarity, that short-term ease can create long-term problems. We understand the hesitation to deviate from standard materials—especially when dealing with building compliance—but specifying non-corrosive alternatives from the start is critical. The right material ensures the living wall system remains functional, healthy, and low-maintenance for years to come.

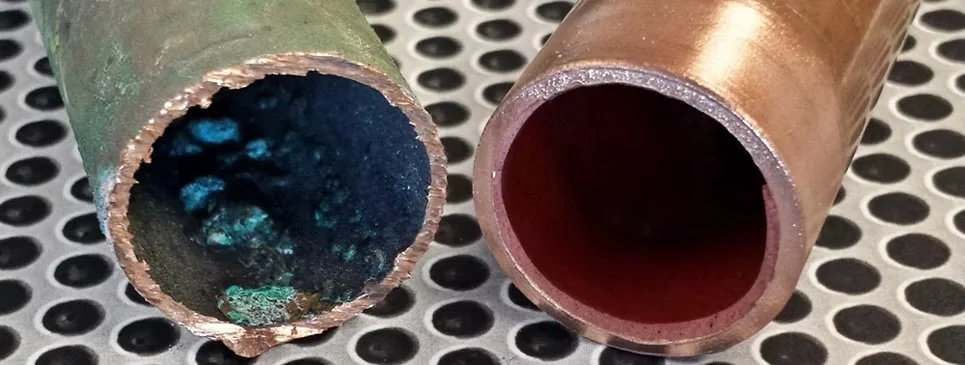

Copper corrosion in pipes occurs when copper reacts with water, oxygen, or other substances, forming copper oxide and other compounds that degrade the pipe’s integrity. Factors such as water pH, temperature, and chemical content influence the rate of corrosion. On average, living wall companies schedule fertilizer to be injected daily during feeding months, alternating with fresh-water months or every other day, alternating with fresh-water days.

Copper and Fertilizer: A Corrosive Mix for Living Wall Systems

Rapid corrosion: Copper reacts aggressively with the salts and acids in most plant fertilizer blends, albeit organic. Once corrosion begins, copper ions leach into the irrigation, feeding the living walls.

Plant toxicity: Though copper is essential in trace amounts, excessive copper:

Impairs nutrient absorption

Causes chlorosis and necrosis

Inhibits photosynthesis, root development, and leaf extension pmc.ncbi

What begins as invisible damage quickly leads to visible decline—yellowing leaves, patchy growth, and eventual plant death, especially in indoor green walls or walls using drip irrigation emitters.

Real-World Example: Clogged Emitters and Dying Plants

In the green wall project shown above, the general contractors installed copper piping despite clear instructions from the living wall design/build team to use non-corrosive CPVC. Both the on-site requirement documents and custom shop drawings specifically called for non-corrosive plumbing, yet copper lines were run and walls were closed up before the mistake was addressed.

As a result, the living wall maintenance team was left to troubleshoot a compromised system and replace failing plant material. Under normal conditions—when the specified non-corrosive piping is used—this system averages an impressively low 2% annual plant replacement rate. This is a significant performance advantage compared to the industry average of 15–30%, underscoring the importance of following material specifications from the outset. The copper-fed irrigation setup used ½” main lines reduced to ¼” emitters—standard for many installations—but over time, the system began to fail. Within just two years, corrosion debris from the copper began clogging the micro emitters, cutting off water flow to entire sections of the wall. This not only caused plant loss but also eroded the client’s confidence in the installation.

Hidden Costs: Why Copper Piping Hurts Living Wall ROI

The hidden cost of copper plumbing in plant wall systems includes:

More frequent maintenance visits

Increased plant replacements

Frustrated clients convinced “living walls don’t work”

Damaged reputation for designers, architects, and installers

This breakdown erodes both trust and budget. And in an industry where biophilic design is gaining traction as a wellness-forward, sustainable building solution, we can’t afford these setbacks.

Avoiding the Pitfalls That Give Living Walls a Bad Name

Living wall professionals are already facing a steep uphill battle due to the price of the system itself and ongoing maintenance costs, which can be a deterrent for some clients. When a system is designed right, regular maintenance should be a joy—not a burden. We should be showing clients that visits are primarily for hacking back vigorous new growth, not constantly reviving weak or dying plants.

A wall that thrives between visits is a testament to good design. But when copper piping is used, even the best plant selection and system design can't save the wall from the slow breakdown happening behind the scenes.

PVC, CPVC, or PEX: Trusted Alternatives

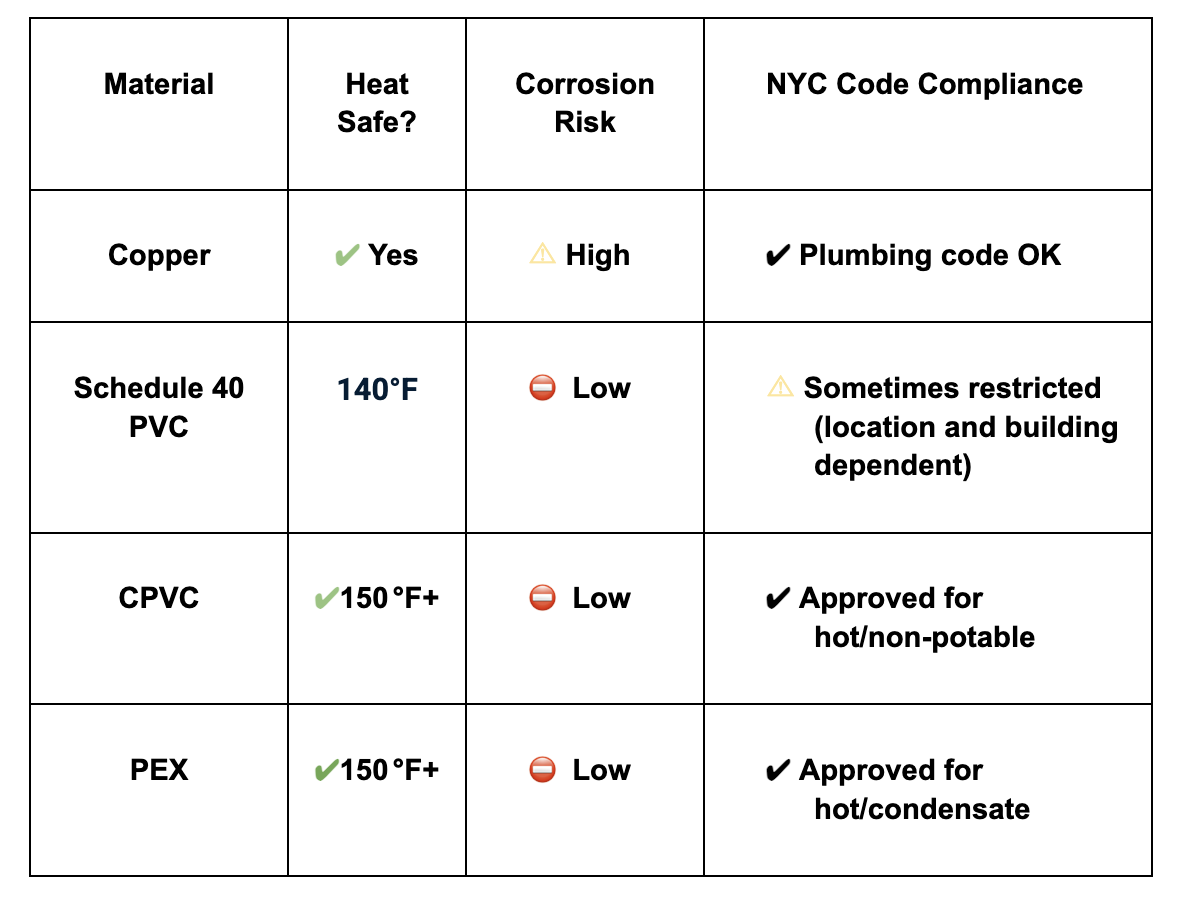

SCHEDULED 40 PVC is only allowed in drain, waste, vent, and water service piping in buildings of three stories or less nyc.gov/buildings/codes

CPVC & PEX are widely accepted in NYC and across the U.S. for non-potable and hot-water runs. NYC Code permits listed CPVC for Category IV appliances—and by extension, for irrigation systems exposed to heat—though unlisted PVC is restricted in venting scopes mdpi.com+1nyc.gov+1nyc.gov+1nyc.gov+1.

PEX is only explicitly permitted for HVAC condensate and hot water piping in NYC nyc.gov+10nyc.gov+10forum.heatinghelp.com+10.

Both of these materials resist corrosion, remain leak-free under heat, and protect your living wall’s integrity.

Best Practices for Specifying Green Wall Irrigation Piping

When designing or installing interior or exterior green wall systems, follow these irrigation best practices:

✅ Always specify non-corrosive piping: Scheduled 40, CPVC or PEX

✅ Prohibit copper runs after fertilizer is introduced

✅ Confirm building code compliance for non-potable water lines

✅ Inform your plumber and GC about material differences and successful alternatives

✅ Highlight long-term maintenance savings to your client

A lush living wall supported by non-corrosive irrigation piping Photo Credit: Urbanstrong

Final Takeaway

Specifying copper piping might seem convenient or not worth the pushback to General Contractors and plumbers on the project, but it sets the stage for corrosion, poor plant health, increased maintenance, and expensive replacements. Switching to CPVC or PEX is a smart, code-compliant strategy that protects both your living wall and portfolio—ensuring thriving installations and satisfied clients in the years to come.

Need help integrating a living wall into your next project?

Urbanstrong collaborates early on with architect and construction teams to ensure the living wall is built in a cost-effective way, offering a seamless and thriving aesthetic. Click here to get the conversation started!

About the Author

Lily has experience across the United States as a biophilic designer, project manager, and living wall design-build specialist. She has a unique perspective on how we can unify our approach to design, planning, and development in a way that recognizes the social, environmental, and economic value of living architecture; to make our urban cities more green.

Today, she closely works with architects/designers and contractors to best offer a technology suited for their budget, design parameters and scale. Lily also serves as Chair of the Green Roof's for Healthy Cities’ Living Wall Committee and Green Plants for Green Buildings Committee member.