Concealed wind uplift restraint for rooftop pavers under ASCE 7-16

A concealed wind uplift paver pedestal system that mechanically restrains rooftop pavers on pedestals where uplift forces exceed paver self-weight, without visible hardware or design compromiseMechanically restrained pedestal pavers designed for ASCE 7-16 wind uplift conditionsCompletely hidden from above. No visible caps, plates, or surface-mounted hardwareEasily clicks in place for quick install with no adhesives or fastenersCompatible with concrete and porcelain pedestal paversShips fast from our New Jersey warehouse with short Northeast lead timesIdeal for parapet rooftop paver system edge and corner zones

Looking for project-specific information?

Mechanically restrained pedestal pavers for rooftop pavers on pedestals

Mechanically restrained pedestal pavers are now a requirement on many rooftops where wind uplift forces exceed the self-weight of traditional pedestal pavers.Urbanstrong’s Concealed Wind Uplift Assembly system provides positive mechanical restraint for rooftop pavers on pedestals, eliminating reliance on gravity alone and reducing the risk of wind damage to roof assemblies, parapets, and membranes.Designed for pedestal pavers, roof pavers, and rooftop paver systems:Suitable for large roof deck paver systems and pedestal deck systemsProtects against wind damage to roof surfaces in high-wind areasPreserves clean architectural layouts without visible restraint hardware

A concealed solution for pedestal pavers without visible hardware

This system solves wind uplift compliance by restraining each paver at the pedestal connection point, rather than on the surface, preserving clean paving on pedestals while meeting modern wind uplift requirements.No exposed clips, caps, or surface platesCompatible with Urbanstrong’s Atlantic Line paver roof deck pedestal systems and raised paving systems (more lines being added later in 2026)Suitable for high wind resistant roofing material strategiesDesigned for rooftop pavers, podiums, and parapet conditions

Why teams choose this approach

Meets ASCE 7-16 uplift requirements without visible hardwareAvoids late-stage redesigns and retrofit costsPreserves architectural intent in parapet and edge zonesReduces long-term wind damage to roof assemblies

-

Why rooftop pavers on pedestals now require mechanical restraint under ASCE 7-16

ASCE 7-16 changed how wind uplift on roofs is calculated, replacing uniform assumptions with zone-based pressures that intensify at edges, corners, and parapets. As this standard is adopted across more jurisdictions, many projects now calculate uplift forces that exceed the self-weight of pedestal pavers, making gravity-only systems inadequate.

- Roof uplift is calculated by zone, not averaged

- Parapet rooftop paver system conditions see the highest pressures

- Rooftop pavers are treated as components subject to uplift

- Mechanical restraint is required to prevent wind damage to roof assemblies

-

What happens when pedestal pavers are not restrained against wind uplift

Unrestrained pedestal pavers increase the likelihood of roof damage from storms, safety hazards, and costly post-event remediation.

- Wind damage to roof membranes and assemblies

- Pavers becoming airborne during severe weather

- Failed plan review or permitting delays

- Wind damage roof repair and retrofit costs

- Increased liability exposure for designers, contractors, and owners

The problem with most pedestal paver systems

Most pedestal paver systems address wind uplift with visible, surface-mounted clips or caps. While effective structurally, these elements often disrupt the clean, uniform appearance designers are trying to achieve on rooftop decks.

Our concealed approach eliminates that tradeoff by restraining each paver at the pedestal connection point rather than on the surface, preserving clean paving on pedestals while meeting modern wind uplift requirements.No exposed clips, caps, or surface platesCompatible with Urbanstrong’s Atlantic Line paver roof deck pedestal systems and raised paving systems (more lines to be added in 2026)Suitable for high wind resistant roofing material strategiesDesigned for rooftop pavers, podiums, and parapet conditions

How the concealed wind uplift paver pedestal system works

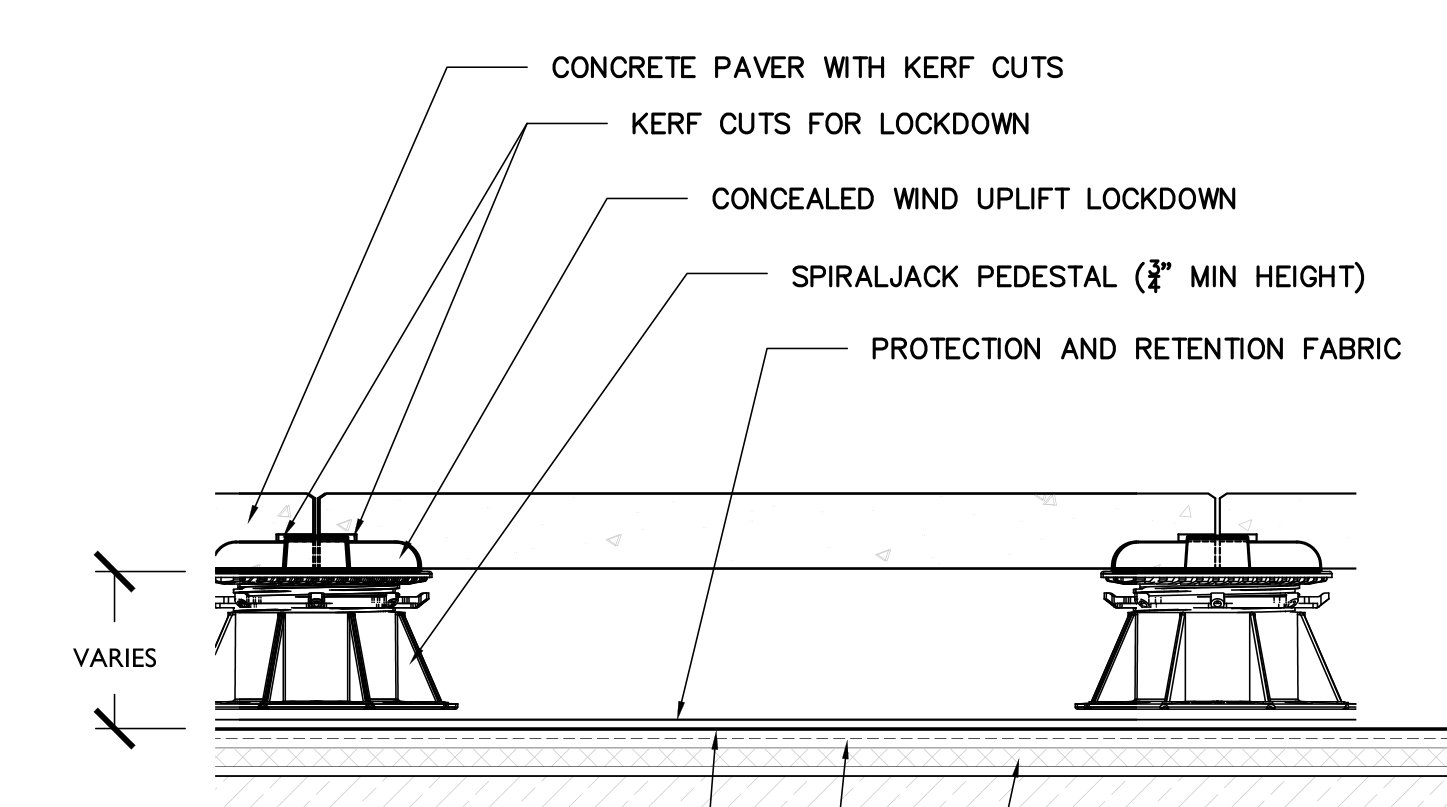

Hidden paver pedestal wind uplift detail

This system uses a concealed mechanical connection that locks the paver to the pedestal without penetrating the top surface.Precision kerf cut is factory-formed during paver fabricationNo field cutting, drilling, or modification required by the installerLockdown component clicks into the pedestal headNo surface penetration or visible fasteningEach pedestal paver is mechanically restrained against uplift

The result is a secure, level roof deck pedestal system that meets wind uplift demands while preserving clean detailingRoof paver pedestal wind testing and high-wind performance

The concealed wind uplift paver pedestal system has been validated through extreme wind testing to support use on exposed rooftops and high-risk wind zones:

Wind uplift performance tested in Florida to 165 mph, exceeding Category 5 hurricane thresholds (157+ mph)Verified using ASTM D3161 wind resistance testing, a nationally recognized standardEngineered to resist uplift forces calculated under ASCE 7-16Suitable for high-wind, coastal, and elevated rooftop environments

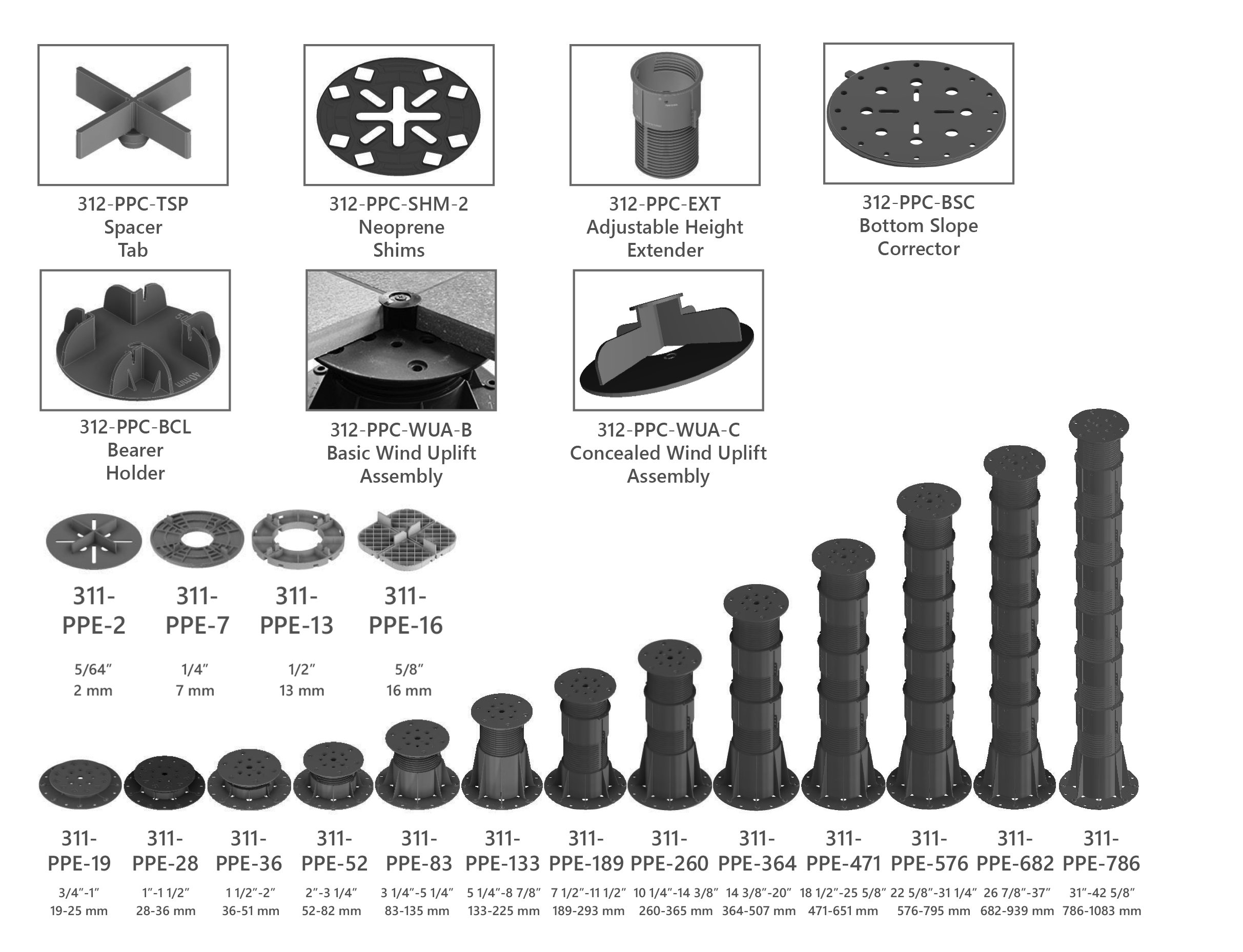

Adjustable pedestal and pedestal system for pavers

The system integrates with common pedestal configurations used across rooftop installations:

Works with Urbanstrong’s adjustable pedestals and adjustable paver pedestalsSupports tile pedestal systems, including deck tile pedestal systemsCompatible with Urbanstrong’s floating pavers, floating paving, and raised paving systemsSuitable for rooftop deck pedestals, balcony pedestals, and patio pedestal system

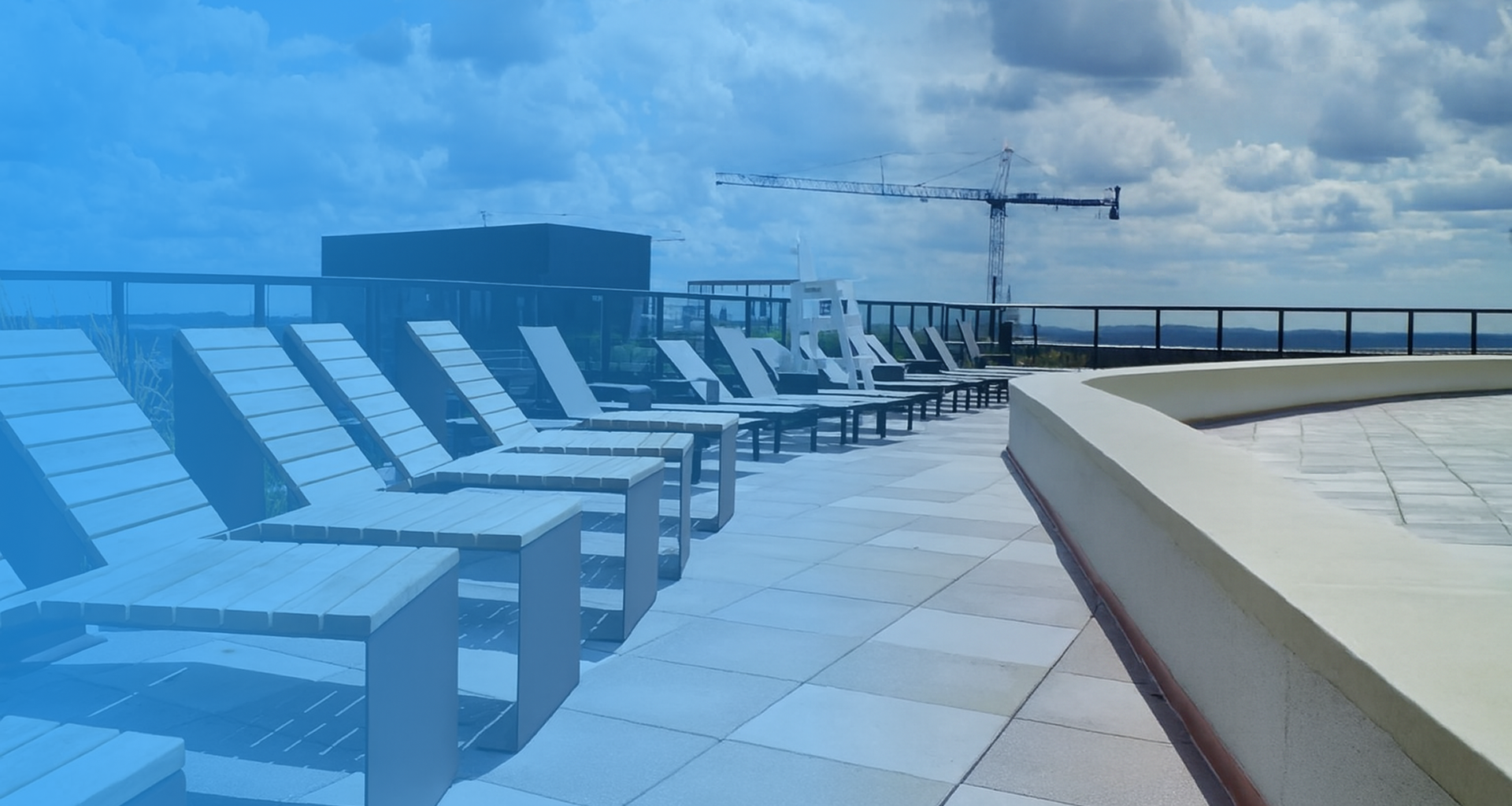

Roof deck paver system applications

This system is used wherever rooftop pavers are exposed to wind uplift and edge conditions.Rooftop pavers and rooftop deck pedestalsPedestal paver pool deck installationsMultifamily and condo podiumsHospitality rooftops and terracesUniversities and institutional buildingsGreen roofs with integrated paving on pedestals

Who specifies and installs pedestal paver systems

-

For architects and engineers

Architects and engineers specify this system to address wind uplift requirements without compromising design intent.

Alignment with ASCE 7-16 wind uplift calculations

Cleaner detailing for parapet and edge zones

Reduced plan review risk

Lower professional liability exposure

-

For contractors and installers

Contractors choose this system for faster installation, fewer callbacks, and predictable performance.

Factory-kerfed pavers arrive job-ready, with no on-site cutting or specialty labor required

No surface hardware to align or conceal

Reduced wind damage and lower long-term roof maintenance risk

Reliable availability from a Northeast distribution point

Short lead times for roof pedestal systems in the Northeast

All systems ship from our New Jersey warehouse, supporting fast delivery for active construction schedules.Short lead times across the NortheastReliable supply for phased rooftop projectsIdeal for time-sensitive installations

Warranty and long-term performance

Urbanstrong’s Atlantic Line pavers used with the concealed wind uplift system carry a 5-year standard warrantyAn additional 5-year warranty extension is available with documented owner participationThis represents one of the longest warranties currently available for wind uplift–rated pedestal paver system

Pedestal paver system FAQ

-

Mechanically restrained pedestal pavers are pavers that are physically locked to their pedestals to prevent uplift and movement caused by wind forces.

-

Rooftop pavers are exposed to wind uplift forces that can exceed their weight, especially under ASCE 7-16. Without restraint, pavers can lift and cause roof damage.

-

Yes. Urbanstrong’s concealed wind uplift restraint systems has been engineered to work in narrow conditions such as single rows of pavers, perimeter bands, and non-vegetated zones around green roofs. These edge conditions are often where wind uplift pressures are highest, so restraint is especially important even when the paved area is limited to a single 24-inch course or similar layout.

Our concealed system addresses this by modifying how the restraint engages the paver, using reduced tab counts or alternate engagement points to accommodate linear runs, herringbone patterns, or edge detailing. Urbanstrong’s concealed wind uplift solution is now available in configurations specifically designed for these conditions, including two-tab and three-tab units that allow secure restraint for single-row installations and perimeter zones. In these applications, kerf locations are adjusted to align with the restraint geometry while preserving a clean, concealed appearance.

-

Cap-based systems rely on visible surface hardware. A concealed system restrains the paver at the pedestal connection point, preserving clean design while improving performa

-

Hanover’s Guardian Paver System resists wind uplift using surface-visible restraint elements installed at the corners or intersections of each paver. These components mechanically tie adjacent pavers together to increase collective resistance to uplift forces.

Because the restraints remain visible in the finished deck surface, they can interrupt the clean appearance many designers prefer.

Urbanstrong offers a concealed wind uplift solution that restrains pavers at the pedestal connection point rather than on the surface, allowing teams to meet wind uplift requirements without visible hardware. -

The Hidden LokDown System uses a concealed kerf-cut connection to restrain its dry cast pavers against wind uplift. Kerf durability depends on the manufacturing method of the paver, particularly flexural strength at the corner.

Dry cast pavers generally have lower flexural strength than wet cast pavers, which can increase susceptibility to corner chipping or breakage at the kerf during handling or installation. Urbanstrong pairs its concealed wind uplift system with wet cast pavers, which typically offer higher density, improved freeze-thaw durability, and greater resistance to kerf-related chipping in rooftop environments.

-

Traditional wind uplift systems for rooftop pavers often rely on surface-mounted clips, caps, plates, or bolt-down assemblies. While effective structurally, these systems can increase total project cost due to additional labor, alignment time, and coordination required during installation. In some cases, aesthetics-driven redesigns or late substitutions can further increase costs.

Concealed wind uplift systems are typically evaluated not just on material cost, but on overall installed cost. Urbanstrong’s concealed wind uplift system is designed to be competitively priced for rooftop paver projects while supporting faster installation. Urbanstrong’s system installs quickly, without adhesives or surface fasteners, thereby reducing labor time.

-

IteLead times for wind uplift–rated pedestal paver systems vary widely depending on manufacturing location, testing requirements, and regional distribution. Some systems are produced far from the project site or require longer fabrication cycles, which can introduce scheduling risk, especially on fast-track or phased rooftop projects.

Concealed systems that are regionally stocked or distributed can significantly reduce delivery timelines and help teams respond quickly to permitting or engineering changes. Urbanstrong, for example, ships concealed wind uplift components from New Jersey distribution point, which supports shorter lead times for projects in the Northeast compared to systems sourced farther away.

-

Yes. The system has been tested in Florida to extreme wind speeds exceeding 160 mph to verify high-wind performance.

-

Yes. Preventing paver movement reduces membrane damage, displaced materials, and ongoing roof maintenance needs.

-

Insurance claims related to wind damage to roof systems may be challenged if pedestal pavers are not properly restrained. Mechanically restraining pavers helps reduce both physical risk and coverage disputes.

Talk to us about your rooftop paver project

We support architects, engineers, and contractors with complete system guidance:

Pedestal paver system details and technical documentationDesign and specification supportLead times and pricing

Detailed specifications, installation guidance, and wind uplift details are available in the technical guide upon request.